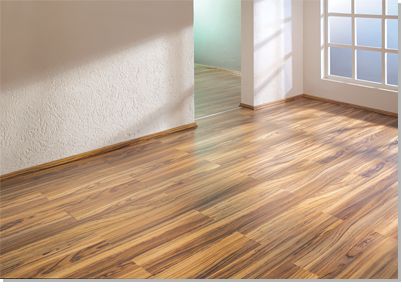

How to lay laminate?

Installation of the laminate flooring:

Most laminate manufacturers include installation instructions with the parquet assortment. The following steps explain the basic procedure. In principle, the manufacturer's installation instructions should always be followed.

The direction of laying

If possible, the direction of laying should be in the direction of the windows or the incidence of light. However, the laying can be done in any direction. Parquet can be laid diagonally or with transition profiles in a wide variety of directions. With normal laying is purchased about 5 percent more that is calculated for the offcut. And in the case of diagonal laying, the waste increases by 10 percent. If the subfloor consists of a plank floor, the parquet elements should be laid across the longitudinal direction of the plank. The recommended impact sound insulation of the parquet manufacturer should be observed. .

Tools

Saw (jigsaw or circular saw), drill (for the skirting boards), hammer, pull iron, tapping block, spacer wedges, putty knife, glue, folding rule, angle, pencil, adhesive tape, cutter knife. .

Material

Laminate, PE foil, impact sound elements, skirting board, transition profile for door transitions, spacers, possibly heating pipe cover For laminates with integrated impact sound, the impact sound elements are of course omitted. A combination foil can also be used, whereby the impact sound elements are connected to the PE foil. Laminates with clic or loc systems are laid floating, i.e. without connecting the panels to the subfloor. This makes it easier to take up the floor again in case of a possible move, repair or renovation. .

Preliminary work

Determine the size of the room, where length times width gives the square amount of laminate, to which is added about 5% offcut. If the laminate is installed on a mineral substrate (concrete, screed, asphalt), a PE film is still needed as a vapor barrier to control the rising damp. In addition, the impact sound insulation elements, which can also be a combination film, which has both integrated. When laying laminate on wooden floors, wooden floorboards, etc., the PE film is unnecessary.

The delivered laminate flooring was stored in sealed packages for 48 hours in the room where it will be laid. The residual moisture contained in it has adapted to the environment, thus preventing the formation of joints due to excessive contraction or swelling of the panels. The laminates are freed from their packaging and in good light the panels can be sorted according to color gradations or the course of the grain.

Now the first sheet of PE film is laid out. Since it should protrude about 10 cm on the sides of the wall, it is pulled up the wall and fixed with adhesive tape. This is followed by the impact sound insulation, which is applied to the vapor barrier film. If the laminate has an integrated impact sound insulation, this is unnecessary and, of course, with a combination film. .

What to consider when laying laminate:

The vapor barrier

Mineral substrates such as screed, asphalt, concrete require a so-called vapor barrier to prevent the penetration of moisture from the substrate, into the parquet floor. For this purpose, plastic films such as PE film or polyethylene are used. Here, too, there are differences in terms of impermeability and permeability, the vapor permeability is specified as sd value.

These films are laid in sheets and fixed with adhesive tape. They must be laid only on mineral substrates such as screed, concrete, asphalt, for example, this is particularly important in rooms without basements and new buildings. However, even if these mineral substrates have been heated in the home for several decades, it is generally necessary to install a vapor barrier, since under certain climatic conditions water vapor can condense in the floor area as condensation and cause structural damage. The vapor barrier is laid in the form of a trough. The sheets are laid side by side, overlapping by about 20 centimeters and fixed with adhesive tape. In the case of wooden subfloors, no vapor barrier should be installed to ensure the natural circulation of moisture. .

The impact sound insulation

For impact sound insulation are particularly suitable felt sheets, foam boards, cork mats, which intercept and absorb the sound that occurs when walking on the parquet floor. When laying parquet on underfloor heating, when choosing the impact sound insulation, pay attention to the thermal resistance, so as not to reduce the effectiveness of underfloor heating. The thermal resistance (WDW) of a material determines the degree of insulating effect. The higher the value, the more insulating the material is. Therefore, the value should be low and not exceed 0.15 sq.m K/W to achieve good thermal transmittance and allow the underfloor heating system to operate economically. Thermal resistance depends on the thickness and density of the material. According to the manufacturer, parquet has a value of 0.05 to 0.10 sqm K/W. To this is added the value of the impact sound to be used, as well as the value of the vapor barrier. Not to forget then the insulating effect of the air cushion between the individual materials, which can not be calculated exactly, but should be taken into account. It is recommended to glue the floor over the entire surface to avoid an air insulation layer between the substrate and parquet. .

The subfloor

As a substrate for the parquet floor are suitable screed, concrete, asphalt, chipboard structures, wooden floorboards, hard coverings such as PVC, stone, ceramics. The condition of the subfloor should be aligned so that the parquet floor can be installed according to the manufacturer's installation instructions. The subfloor should be level. Differences of more than three millimeters in the subfloor must be sanded or filled. To determine these unevennesses use a spirit level or a straightedge. The subfloor must be firm to walk on and must not spring. Thus, carpeting is not suitable as a substrate and must be removed before installation. This is because the carpet, which lies under the parquet floor, causes a springy movement when the parquet surface is walked on and strong pressure in the edge area. This would destroy the tongue and groove joint or clic connection and lead to the formation of gaps. Likewise, for hygienic reasons (mold, odor), the carpet should be removed before laying the parquet. The subfloor must be absolutely flat, clean and solid. Even if impact sound insulation were laid on the carpet, this problem would not be solved. The subfloor must not bounce or buckle under load, but must be absolutely sound before the parquet can be installed. Thus, carpeting under a hardwood floor should generally be removed. .

Walkability

Since parquet floors do not require any oils or sealants, as is the case with the various wood floors, the parquet floor can be walked on immediately after installation. Also, first half of a room can be covered with parquet flooring and the appropriate furniture can be put back on it, and then the other half of the room can be further covered with parquet flooring. .

The wall spacing

Attention must be paid to the wall spacing, the expansion joints are fixed by spacer wedges, so that the parquet floor gets space and can 'work' accordingly like all wooden floors. The term 'work' refers to the swelling and shrinkage processes of the wood or wood-based material caused by the natural hygroscopic behavior, the absorption and release of moisture. In addition, the dimensional behavior of parquet flooring elements is affected by heat or cold acting from above or below. Therefore, it is important that the parquet floor has room to work in order to avoid possible damage later. These damages can be: open joints, swelling, compression in the joint area with decorative damage, standing up of the floor (waves). The distance between the parquet floor and the wall and all fixed components, should be 1.2 cm to 1.5 cm and is determined during installation with spacer wedges. Expansion joints should also be taken into account when laying parquet, especially if the area to be laid is more than eight meters in the longitudinal direction or width, and if it is planned to lay across rooms. .

Laying laminate

Removal of the old subfloor

Lay out vapour barrier

Bonding the vapour barrier

Lay insulation underlay to reduce the impact sound

Overall structure in the profile view

Fix the spacers to the wall and lay the first row

Continue the second row with the simple click system

Simply press down until the spring clicks into place

Ready to lay the floor

Quickly install the skirting boards, distance the

Mark the fastening clips.

Pre-drill the fixing clips:

Fitting skirting boards

Mitre cut in the corners

Measure and insert transition profile

Fitting the transition profile cover strip

Fixing skirting boards in the room passageway

Ready!

A quick dusting

Now quickly wipe once damp

Perfect, the new floor lies